Original Version

Rule 48

48 Ultimate Strength Of Materials

Values used for the ultimate strength of materials, in connection with the safety specified in Rule 44 shall be not more than as follows:

48.1 Wood

Values used for moduli of rupture for wood in bending, in conjunction with the safety factors given in Rule 44, shall not exceed those shown in Table 5.

Table

5 |

||

Species |

Modulus of rupture in bending |

|

Sawed rectangular poles, crossarm, etc. (a) |

Round Poles |

|

Cedar, western red |

4,700 lbs. Per sq in |

6,000 lbs. Per sq in |

Douglas fir, sense |

6,300 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Douglas fir, not dense |

5,800 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Fir, white or red, local |

4,700 lbs. Per sq in |

5,600 lbs. Per sq in |

Pine, southern yellow, dense |

6,300 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Pine, southern yellow, not dense |

5,800 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Redwood, virgin |

5,300 lbs. Per sq in |

6,200 lbs. Per sq in |

Redwood, second growth |

3,900 lbs. Per sq in |

4,600 lbs. Per sq in |

(a) Figures given are for select structural

grade of material under short time loading with the neutral plane parallel

to a side. Multiply the values shown by 1.4 where the neutral plane

is on the diagonal of a square. Multiply the given values by 0.55 where

the loading being considered is a long time loading (continuous load for

one year or more).

(b)

Where poles meet specifications of American Standards

Association, 05.1-1963 for Douglas Fir Poles and for southern Pine

Poles this value may be increased to not more than 8,000 lbs. Per square

inch. Such poles shall be suitable preservative treatment.

48.2 Structural Material (other than wood)

Structural members and their connections, shall be designed and constructed so that the structures and parts thereof will not fail or be seriously distorted at any load less than the maximum working loads developed under the construction arrangement with loadings as specified in Rule 43) multiplied by the safety factors specified in Rule 44.

The safety factors specified in Rule 44 shall be applied as follows to structural steel:

Tensions and Bending: The yield point, 33,000 pounds per square inch, shall be divided by the safety factor to determine the maximum allowable working stress.

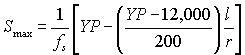

Compression: The maximum allowable working stress shall be calculated by the following formula:

where Smax = maximum allowable working stress, lbs per sq in.

fs = safety factor specified in Rule 44

YP = yield point of the steel, 33,000 lbs per sq in.

l = unsupported length of member, inches

r = radius of gyration of member, inches

Shear: The ultimate tensile strength, 60,000 pounds per square inch, shall be multiplied by 2/3 and divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

Where the figures given are used, structural steel shall conform to Standards Specifications A7-39 of American Society for Testing Materials for carbon steel of structural quality. Other values may be used for steel of other strength provided the yield point and ultimate tensile strength are determined by test.

For other structural materials (other than concrete), the safety factor specified in Rule 44 shall be applied as follows:

Tension: The yield strength of the material used shall be divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

Compression: The ultimate compressive strength of the material used be divided by the safety factor specified in Rule 44 to obtain the allowable working stress. The ultimate compressive strength shall be determined by suitable formulas for material used, considering yield strength of the material, modulus of elasticity, slenderness ratio and eccentricity of connection. In no case shall the ultimate compressive stress be greater than the yield strength of the material.

Shear: The ultimate shear strength of the material used be divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

48.3 Concrete

A. Reinforced Concrete

Values used for ultimate strengths of reinforced concrete, in conjunction with safety factors given in Rule 44, shall not exceed the following:

Reinforcing steel, tensile or compressive strength, pounds per square inch |

55,000 |

Concrete, 1:2:4 mixture |

Age |

Compressive Strength |

7 days |

900 lbs per sq in. |

|

30 days |

2,400 lbs per sq in. |

|

90 days |

3,100 lbs per sq in. |

|

6 mos |

4,400 lbs per sq in. |

If reinforced concrete is designed for higher strength values which are proven by test, such values may be used in lieu of the figures given.

B. Prestressed Concrete

Structural Members and their connections shall he designed and constructed so that the structures and parts thereof will not fail or be seriously distorted at any load less than their maximum working loads (developed under the current construction arrangements with loadings as Specified in Rule 43) multiplied by the safety factor specified in Rule 44."

The minimum strength of the materials used in prestressed concrete structures used in conjunction with the safety factors given in Table 4 shall be as follows:

Prestressing |

yield strength 40,000 lb.. per sq. inch |

SteelReinforcing Steel |

yield strength 188,000 lbs. per sq. inch |

Concrete |

compressive strength 4,000 lbs. per sq. inch at 28 days |

Other strength Values may be used provided the strength values used for design are proven by tests.

48.4 Conductors, Span Wires, Guys and Messengers

Values used for ultimate strengths of wires and cable shall not exceed those given in Appendix B. The ultimate strengths given in Tables 17 to 24 of Appendix B, except for medium-hard-drawn copper, are based on the minimum ultimate strengths given in the standards specifications of the American Society for Testing Materials. The ultimate strengths given in Appendix B for medium-hard-drawn copper based on the standard specifications of the ASTM and provide an allowance above the minimum values of one-quarter of the range between minimum and maximum values. For use of types of wires and cables of other materials not included in Appendix B, values for ultimate strengths similarly derived from specifications are nonexistent, makerís specifications may be used provided that tests have been made which shall justify the makerís rating for ultimate strength.

48.5 Tower or Pole Foundations and Footings

In calculating the resistance of foundations or footings of towers, poles and pole line structures to uplifts, the weight of concrete shall be taken as not more than 145 pounds per cubic foot and the weight of earth (calculated 30 degrees from the vertical) shall be taken as not more than 90 pounds per cubic foot. The resistance of soil to the depression of foundations or footings shall be calculated from the best available data on the soil in question. In lieu of calculation, the strength of foundations or footings against uplift or depression may be determined by tests under the soil conditions obtaining.

48.6 Metallic Service and Meter Poles

Metallic service and meter poles shall be designed and constructed so that the poles and parts thereof will not fail or be seriously distorted at any load less than the maximum working loads (see Rule 43 for loadings) multiplied by the safety factors specified in Table 4, Rule 44. The safety factors specified in Table 4, Rule 44 shall be applied as follows:

Tension: The yield strength of the metal used shall be divided by the safety factor specified in Table 4, Rule 44 to determine the maximum allowable working stress.

Compression: The critical. buckling strength of the material used, as determined by applicable formulas employing the effective slenderness ratio and yield strength, shall be divided by the safety factors specified in Table 4, Rule 44, to determine the maximum allowable working stress.

Strikeout and Underline Version

Rule 48

48 Ultimate Strength Of Materials

Structural members and their connections shall be designed and constructed so that the structures and parts thereof will not fail or be seriously distorted at any load less than their maximum working loads (developed under the current construction arrangements with loadings as specified in Rule 43 multiplied by the safety factor specified in Rule 44.

Values used for the ultimate strength of materials shall comply with the safety factors specified in Rule 44.

Values used for the ultimate strength of materials, in connection

with the safety specified in Rule 44 shall be not more than as follows:

48.1 Wood

Values used for moduli of rupture for wood in bending, in conjunction with the safety factors given in Rule 44, shall not exceed those shown in Table 5.

Table

5 |

||

Species |

Modulus of rupture in bending |

|

Sawed rectangular poles, crossarm, etc. (a) |

Round Poles |

|

Cedar, western red |

4,700 lbs. Per sq in |

6,000 lbs. Per sq in |

Douglas fir, sense |

6,300 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Douglas fir, not dense |

5,800 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Fir, white or red, local |

4,700 lbs. Per sq in |

5,600 lbs. Per sq in |

Pine, southern yellow, dense |

6,300 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Pine, southern yellow, not dense |

5,800 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Redwood, virgin |

5,300 lbs. Per sq in |

6,200 lbs. Per sq in |

Redwood, second growth |

3,900 lbs. Per sq in |

4,600 lbs. Per sq in |

(a) Figures given are for select structural

grade of material under short time loading with the neutral plane parallel

to a side. Multiply the values shown by 1.4 where the neutral plane

is on the diagonal of a square. Multiply the given values by 0.55 where

the loading being considered is a long time loading (continuous load for

one year or more).

(b)

Where poles meet specifications of American Standards

Association, 05.1-1963 for Douglas Fir Poles and for southern Pine

Poles this value may be increased to not more than 8,000 lbs. Per square

inch. Such poles shall be suitable preservative treatment.

48.2 Structural

Material (other than wood) Steel

Structural members

and their connections, shall be designed and constructed so that the structures

and parts thereof will not fail or be seriously distorted at any load less than

the maximum working loads developed under the construction arrangement with

loadings as specified in Rule 43) multiplied by the safety factors specified in

Rule 44.

The safety factors specified in Rule 44 shall be applied as follows to structural steel:

Tensions and Bending: The yield point, 33,000 pounds per square inch, shall be divided by the safety factor to determine the maximum allowable working stress.

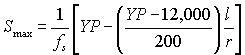

Compression: The maximum allowable working stress shall be calculated by the following formula:

where Smax = maximum allowable working stress, lbs per sq in.

fs = safety factor specified in Rule 44

YP = yield point of the steel, 33,000 lbs per sq in.

l = unsupported length of member, inches

r = radius of gyration of member, inches

Shear: The ultimate tensile strength, 60,000 pounds per square inch, shall be multiplied by 2/3 and divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

Where the figures given are used, structural steel shall conform to Standards Specifications A7-39 of American Society for Testing Materials for carbon steel of structural quality. Other values may be used for steel of other strength provided the yield point and ultimate tensile strength are determined by test.

For other structural

materials (other than concrete), the safety factor specified in Rule 44 shall

be applied as follows:

Tension: The yield

strength of the material used shall be divided by the safety factor specified

in Rule 44 to determine the maximum allowable working stress.

Compression: The

ultimate compressive strength of the material used be divided by the safety

factor specified in Rule 44 to obtain the allowable working stress. The ultimate compressive strength shall be

determined by suitable formulas for material used, considering yield strength

of the material, modulus of elasticity, slenderness ratio and eccentricity of

connection. In no case shall the

ultimate compressive stress be greater than the yield strength of the material.

Shear: The ultimate shear strength of the material

used be divided by the safety factor specified in Rule 44 to determine the

maximum allowable working stress.

48.3 Concrete

A. Reinforced Concrete

Values used for ultimate strengths of reinforced concrete, in conjunction with safety factors given in Rule 44, shall not exceed the following:

Reinforcing steel, tensile or compressive strength, pounds per square inch |

55,000 |

Concrete, 1:2:4 mixture |

Age |

Compressive Strength |

7 days |

900 lbs per sq in. |

|

30 days |

2,400 lbs per sq in. |

|

90 days |

3,100 lbs per sq in. |

|

6 mos |

4,400 lbs per sq in. |

If reinforced concrete is designed for higher strength values which are proven by test, such values may be used in lieu of the figures given.

B. Prestressed Concrete

Structural Members and their connections shall he designed and constructed so that the structures and parts thereof will not fail or be seriously distorted at any load less than their maximum working loads (developed under the current construction arrangements with loadings as Specified in Rule 43) multiplied by the safety factor specified in Rule 44."

The minimum strength of the materials used in prestressed concrete structures used in conjunction with the safety factors given in Table 4 shall be as follows:

Prestressing |

yield strength 40,000 lb.. per sq. inch |

SteelReinforcing Steel |

yield strength 188,000 lbs. per sq. inch |

Concrete |

compressive strength 4,000 lbs. per sq. inch at 28 days |

Other strength Values may be used provided the strength values used for design are proven by tests.

48.4 Other Structural Materials

For other structural materials (other than concrete), the safety factor specified in Rule 44 shall be applied as follows:

Tension: The yield strength of the material used shall be divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

Compression: The ultimate compressive strength of the material used be divided by the safety factor specified in Rule 44 to obtain the allowable working stress. The ultimate compressive strength shall be determined by suitable formulas for material used, considering yield strength of the material, modulus of elasticity, slenderness ratio and eccentricity of connection. In no case shall the ultimate compressive stress be greater than the yield strength of the material.

Shear: The ultimate shear strength of the material used be divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

48.45

Conductors,

Span Wires, Guys and Messengers

Values used for ultimate strengths of wires and cable shall not exceed those given in Appendix B. The ultimate strengths given in Tables 17 to 24 of Appendix B, except for medium-hard-drawn copper, are based on the minimum ultimate strengths given in the standards specifications of the American Society for Testing Materials. The ultimate strengths given in Appendix B for medium-hard-drawn copper based on the standard specifications of the ASTM and provide an allowance above the minimum values of one-quarter of the range between minimum and maximum values. For use of types of wires and cables of other materials not included in Appendix B, values for ultimate strengths similarly derived from specifications are nonexistent, makerís specifications may be used provided that tests have been made which shall justify the makerís rating for ultimate strength.

48.56

Tower

or Pole Foundations and Footings

In calculating the resistance of foundations or footings of towers, poles and pole line structures to uplifts, the weight of concrete shall be taken as not more than 145 pounds per cubic foot and the weight of earth (calculated 30 degrees from the vertical) shall be taken as not more than 90 pounds per cubic foot. The resistance of soil to the depression of foundations or footings shall be calculated from the best available data on the soil in question. In lieu of calculation, the strength of foundations or footings against uplift or depression may be determined by tests under the soil conditions obtaining.

48.67

Metallic Service and Meter Poles

Metallic service and meter poles shall be designed and constructed so that the poles and parts thereof will not fail or be seriously distorted at any load less than the maximum working loads (see Rule 43 for loadings) multiplied by the safety factors specified in Table 4, Rule 44. The safety factors specified in Table 4, Rule 44 shall be applied as follows:

Tension: The yield strength of the metal used shall be divided by the safety factor specified in Table 4, Rule 44 to determine the maximum allowable working stress.

Compression: The critical. buckling strength of the material used, as determined by applicable formulas employing the effective slenderness ratio and yield strength, shall be divided by the safety factors specified in Table 4, Rule 44, to determine the maximum allowable working stress.

Final Version

Rule 48

48 Ultimate Strength Of Materials

Structural members and their connections shall be designed and constructed so that the structures and parts thereof will not fail or be seriously distorted at any load less than their maximum working loads (developed under the current construction arrangements with loadings as specified in Rule 43 multiplied by the safety factor specified in Rule 44.

Values used for the ultimate strength of materials shall comply with the safety factors specified in Rule 44.

48.1 Wood

Values used for moduli of rupture for wood in bending, in conjunction with the safety factors given in Rule 44, shall not exceed those shown in Table 5.

Table

5 |

||

Species |

Modulus of rupture in bending |

|

Sawed rectangular poles, crossarm, etc. (a) |

Round Poles |

|

Cedar, western red |

4,700 lbs. Per sq in |

6,000 lbs. Per sq in |

Douglas fir, sense |

6,300 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Douglas fir, not dense |

5,800 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Fir, white or red, local |

4,700 lbs. Per sq in |

5,600 lbs. Per sq in |

Pine, southern yellow, dense |

6,300 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Pine, southern yellow, not dense |

5,800 lbs. Per sq in |

6,800 (b) lbs. Per sq in |

Redwood, virgin |

5,300 lbs. Per sq in |

6,200 lbs. Per sq in |

Redwood, second growth |

3,900 lbs. Per sq in |

4,600 lbs. Per sq in |

(a) Figures given are for select structural

grade of material under short time loading with the neutral plane parallel

to a side. Multiply the values shown by 1.4 where the neutral plane

is on the diagonal of a square. Multiply the given values by 0.55 where

the loading being considered is a long time loading (continuous load for

one year or more).

(b)

Where poles meet specifications of American Standards

Association, 05.1-1963 for Douglas Fir Poles and for southern Pine

Poles this value may be increased to not more than 8,000 lbs. Per square

inch. Such poles shall be suitable preservative treatment.

48.2 Steel

The safety factors specified in Rule 44 shall be applied as follows to structural steel:

Tensions and Bending: The yield point, 33,000 pounds per square inch, shall be divided by the safety factor to determine the maximum allowable working stress.

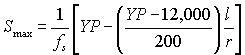

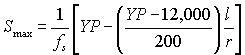

Compression: The maximum allowable working stress shall be calculated by the following formula:

where Smax = maximum allowable working stress, lbs per sq in.

fs = safety factor specified in Rule 44

YP = yield point of the steel, 33,000 lbs per sq in.

l = unsupported length of member, inches

r = radius of gyration of member, inches

Shear: The ultimate tensile strength, 60,000 pounds per square inch, shall be multiplied by 2/3 and divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

Where the figures given are used, structural steel shall conform to Standards Specifications A7-39 of American Society for Testing Materials for carbon steel of structural quality. Other values may be used for steel of other strength provided the yield point and ultimate tensile strength are determined by test.

48.3 Concrete

A. Reinforced Concrete

Values used for ultimate strengths of reinforced concrete, in conjunction with safety factors given in Rule 44, shall not exceed the following:

Reinforcing steel, tensile or compressive strength, pounds per square inch |

55,000 |

Concrete, 1:2:4 mixture |

Age |

Compressive Strength |

7 days |

900 lbs per sq in. |

|

30 days |

2,400 lbs per sq in. |

|

90 days |

3,100 lbs per sq in. |

|

6 mos |

4,400 lbs per sq in. |

If reinforced concrete is designed for higher strength values which are proven by test, such values may be used in lieu of the figures given.

B. Prestressed Concrete

Structural Members and their connections shall he designed and constructed so that the structures and parts thereof will not fail or be seriously distorted at any load less than their maximum working loads (developed under the current construction arrangements with loadings as Specified in Rule 43) multiplied by the safety factor specified in Rule 44.

The minimum strength of the materials used in prestressed concrete structures used in conjunction with the safety factors given in Table 4 shall be as follows:

Prestressing |

yield strength 40,000 lb.. per sq. inch |

SteelReinforcing Steel |

yield strength 188,000 lbs. per sq. inch |

Concrete |

compressive strength 4,000 lbs. per sq. inch at 28 days |

Other strength Values may be used provided the strength values used for design are proven by tests.

48.4 Other Structural Materials

For other structural materials (other than concrete), the safety factor specified in Rule 44 shall be applied as follows:

Tension: The yield strength of the material used shall be divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

Compression: The ultimate compressive strength of the material used be divided by the safety factor specified in Rule 44 to obtain the allowable working stress. The ultimate compressive strength shall be determined by suitable formulas for material used, considering yield strength of the material, modulus of elasticity, slenderness ratio and eccentricity of connection. In no case shall the ultimate compressive stress be greater than the yield strength of the material.

Shear: The ultimate shear strength of the material used be divided by the safety factor specified in Rule 44 to determine the maximum allowable working stress.

48.5 Conductors, Span Wires, Guys and Messengers

Values used for ultimate strengths of wires and cable shall not exceed those given in Appendix B. The ultimate strengths given in Tables 17 to 24 of Appendix B, except for medium-hard-drawn copper, are based on the minimum ultimate strengths given in the standards specifications of the American Society for Testing Materials. The ultimate strengths given in Appendix B for medium-hard-drawn copper based on the standard specifications of the ASTM and provide an allowance above the minimum values of one-quarter of the range between minimum and maximum values. For use of types of wires and cables of other materials not included in Appendix B, values for ultimate strengths similarly derived from specifications are nonexistent, makerís specifications may be used provided that tests have been made which shall justify the makerís rating for ultimate strength.

48.6 Tower or Pole Foundations and Footings

In calculating the resistance of foundations or footings of towers, poles and pole line structures to uplifts, the weight of concrete shall be taken as not more than 145 pounds per cubic foot and the weight of earth (calculated 30 degrees from the vertical) shall be taken as not more than 90 pounds per cubic foot. The resistance of soil to the depression of foundations or footings shall be calculated from the best available data on the soil in question. In lieu of calculation, the strength of foundations or footings against uplift or depression may be determined by tests under the soil conditions obtaining.

48.7 Metallic Service and Meter Poles

Metallic service and meter poles shall be designed and constructed so that the poles and parts thereof will not fail or be seriously distorted at any load less than the maximum working loads (see Rule 43 for loadings) multiplied by the safety factors specified in Table 4, Rule 44 . The safety factors specified in Table 4, Rule 44 shall be applied as follows:

Tension: The yield strength of the metal used shall be divided by the safety factor specified in Table 4, Rule 44 to determine the maximum allowable working stress.

Compression: The critical. buckling strength of the material used, as determined by applicable formulas employing the effective slenderness ratio and yield strength, shall be divided by the safety factors specified in Table 4, Rule 44 , to determine the maximum allowable working stress.