General Order 64

Appendix D

Method of Determining the Construction Requirements for a typical Crossing of Class H Supply Lines Over an Important Railroad and Signal Lines to Comply with the Requirements of These Rules for Light Loading Conditions.

The purpose of this appendix is to provide an example of a typical crossing of supply lines over railroads and signal lines to determine the various clearances and construction requirements necessary to comply with the rules. The actual construction of the crossing is made to conform to current good practice and indicated where and in what manner the minimum requirements of the rules are exceeded or maintained. The crossing diagram and dimensions are shown on the following page after this appendix. The primary data chosen for the crossing follow:

DATA OF CROSSING.

Number

of Circuits, Voltage and Phase.

Two

3-phase 60,000-volt circuits. One

private telephone circuit.

Configuration.

Power conductors of each circuit in

vertical plane on opposite ends of the crossarms. Private telephone circuit in horizontal plane.

Conductors.

Power circuits-6 No. 00 A.W.G. copper,

medium hard drawn, stranded, bare.

*Private

telephone circuit-2 No. 8 A.W.G.

copper, medium hard drawn, solid, bare.

*It is

assumed that the private signal circuit on the power line pole is run, operated

and maintained consistently, as a signal circuit as defined in Rule 17 (d), and for this reason change in conductor size at the crossing is

required.

Insulators.

Pin Type porcelain, to meet the requirements

of Rules 64 and 126 (d) 3, and 4.

Ties

and Conductor Fastenings.

To

meet the requirements of Rule 62(a).

Pins.

Iron pipe (extra strong) 1 ½ (nominal) X

20 ½ for power conductors pins of each circuit metallically bonded together

to conform to the requirements of Rule 126 (d) 2. 1 ½ X 9 locust pins for conductors of private telephone

circuit.

Crossarms.

Douglas fir 5 Ύ X 5 Ύ X 12-0, 1.9 pin

holes 11/16 hole for pole bolt.

(Telephone circuit crossarm 3 Ό X 4 ½.)

Crossarm

Braces.

To conform to Rule 62(a).

Poles.

Western red cedar National Electric

Light Association specifications.

Pole

Framing.

As per dimensional

diagram.

Location

of Poles.

As per dimensional

diagram.

Length

of Crossing Span.

200 feet

Length

of Adjacent Spans.

150 feet

CONSTRUCTION REQUIREMTNS.

1. Conductor Sags (Normal Conditions, 60°F., no wind).

The

required sags of power and telephone conductors are determined from the minimum

sags curves of Appendix C.

For No. 00

A.W.G. copper, medium hard drawn, stranded, bar Span 200 feet, Curve Sheet,

curve

2, gives the sag as 12.0 inches.

For No. 8

A.W.G. copper, medium hard drawn, solid, bar Span 200 feet, Curve Sheet, curve

2, gives the sag as 13.2 inches.

In the

spans adjacent to the crossing span the supports are at different levels, and the

apparent sags are required. These are

equal to the normal sags for spans of the same length between supports at the

same level. Thus from, the curve

2 of

Appendix C, the apparent sags are 7.2 inches for the No. 8 A.W.G.

wire and 6.9 inches for the No. 00 A.W.G. wire.

2. Conductor Sags (Light Loading 25° F., 8 pounds wind)

Since no ice loading is considered, the vertical sags under the light loading condition will be less than normal sags at 60°F. and no wind. Consequently the clearances provided under light loading will be greater than normal conditions, and it is therefore only necessary to determine the elevations of supports to provide the required clearances under normal conditions, 60°F. and no wind. The tensions in the conductors loaded are found from Tables 13 and 14, Appendix B, to be as follows:

|

Copper Conductors |

150-foot span |

200-foot span |

|

No 00 A.W.G. medium hard drawn, stranded bare |

2,610 lbs. |

2,610 lbs |

|

No 8 A.W.G. medium hard drawn, solid bare |

324 lbs. |

324 lbs. |

3.

Conductor Separations at Supports.

Table 1,

case 6, column F, gives the minimum clearance of the conductors from the center

of the pole for supply conductors of this class as 18 inches. For circuits of the character under

consideration, where vertical configuration is employed, current good practice

employs a spacing of 56 from the center of the pole, which is greatly in

excess of the minimum required.

For a

private telephone circuit, Table 1, case 6, column B, provides a minimum

clearance for conductors of 15 inches from the center of the pole. Eighteen (18) inches is employed in this

case.

4.

Crossarm Spacing.

Table 2,

case 11, column H, gives the minimum vertical separation between wires on

different crossarms on the same poles for 60,000 volt circuits as 4 feet. Note (r) modifies this to allow a conductor

spacing equivalent to the table values for pin spacing of wires of the circuit

voltage which is (by Table 2, case 7, Column H) 36 inches. In the case under discussion the vertical

separation between crossarms has been taken as 56, conforming to current

good practice.

The minimum

separation between the lowest crossarm supporting power conductors and the

crossarm supporting a private telephone circuit is given by Table 2, case 11,

column C, as 6 feet. Current good

practice usually employs an 8-foot separation and it is so taken in this case.

5.

Clearances of Conductors Over Crossarms.

Table 1,

case 9, column F, gives the minimum clearance of conductors in the 60,000-volt

class above the supporting crossarms as 9 inches. Since in this case a 20 ½ pin is employed, the clearance of the

conductor above the crossarm is 15 inches, which is in excess of the minimum

requirements.

Table 1,

case 9, column E, gives the minimum clearance of the private telephone

conductors above the supporting crossarm as 3 inches. This is adhered to in the case discussed.

6.

Vertical Clearance of Conductors Over

Highway, Pole lines and Railroad Tracks.

The poles

supporting the crossing span are 55 feet in length set 7 feet in the

ground. From the dimensions of the pole

framing diagram, the distance from the conductors of the private telephone

circuit to the ground is 286. The

ground level is given as the same elevation the as top of the rail.

The sag of

the signal conductors in the crossing span is given above as 13.2 inches. The plan gives the distances from supporting

pole C to the various structures crossed over as follows:

Telephone pole line 376

Highway (center) 600

Telegraph pole line on R.R r/w 976

Center railroad tracks 1389

Railroad signal pole line 1800

Total length of crossing span, 200 feet.

Considering as an example the clearance of the private telephone circuit conductors above the crossed over telephone pole lead.

This point of crossing is from the nearest crossing pole C 376 or 18.75 percent of the crossing span length. The sag at 18.75 percent of the crossing span length is (from curve 12, Appendix C) 61 percent of the center sag. The center sag is 13.2, making the sag at the point of crossing 13.2 X 0.6 =8.0. Therefore the clearance of private telephone conductors over the top of rail at the point of crossing with the telephone pole line is 286 - 8.0 = 2710. As the top wire of the telephone pole line at this point is given as 24, the clearance at this point from the private telephone circuit conductors will be 310, which is in excess of the minimum required clearance of 2 given by Table 2, case 2, column c.

In a like manner the clearances of the private telephone circuit conductors at the other points of crossing are as follows:

|

Points of Crossing |

Clearance |

Minimum by rules |

|

Highway (center) |

277 |

180 |

|

Telegraph pole line |

35 |

20 |

|

Railroad tracks (center) |

277 |

250 |

|

Railroad signal pole line |

61.3 |

20 |

The clearances of the lower power conductors at the various points of crossing can likewise be computed and are as follows:

|

Points of Crossing |

Clearance |

Minimum by rules |

|

Telephone pole line |

130 |

80 |

|

Highway (center) |

369 |

300 |

|

Telegraph pole line |

127 |

80 |

|

Railroad tracks (center) |

369 |

340 |

|

Railroad signal pole line |

153 |

80 |

7.

Insulators.

In addition

to the electrical requirements set forth in Rules 64 and 126 (d) 3, and 4, the

insulators supporting the supply conductors shall have a safety factor

(mechanical) of over 3 the stresses they will be required to withstand for the

most severe condition of loading applying.

(Rule 52 (c).)

8. Pins, Ties and Conductor Fastenings.

Pins, ties

and conductor fastenings used in connection with pin type insulators shall have

sufficient strength to withstand a tension in the conductor of 700 pounds per

pin or fastening as a minimum (Rule 62 (a)).

When greater strength is necessary they shall be designed to withstand

with a safety factor of 2 the tension in the conductor under the specified

loading condition. In the case under

discussion wrought iron pipe pins are to be employed of the dimensions and

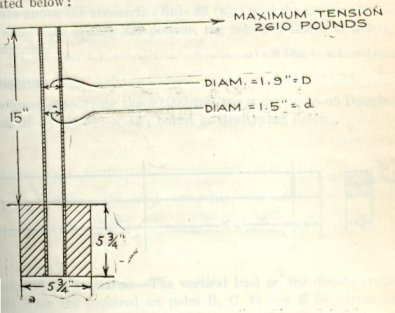

construction indicated below:

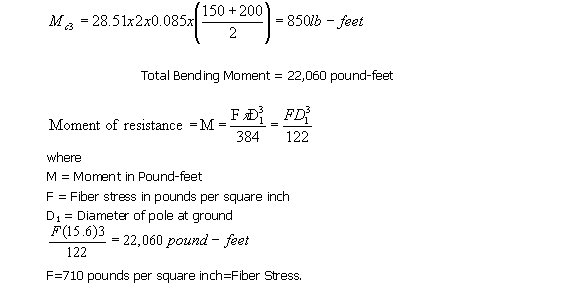

Bending moment (at crossarm) = M = 2,610 X 15=39,150 inch-pounds

Moment of

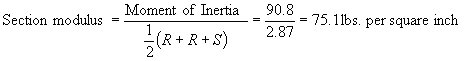

inertia ![]()

where ![]() and

and ![]()

Section

modulus ![]()

Fiber

stress ![]()

where c=D/2

Since the ultimate fiber stress for wrought iron is 45,000 pounds per square inc, a single pin is of this type is insufficient. Four such pins are required to provide a factor of safety of 2 and, as the unbalanced stress may be distruted over one or more poles adjacent to the crossing, double pins are required at poles B, C, D and E.

Conductor fastenings or ties are required to provide a safety factor of (2).

Locust pins 1 ½ X 9 are employed for supporting the private telephone conductors. Since locust pins of these dimensions provide strength up to 1000 pounds tension in the conductor, with the conductor 3 ½ inches above the crossarm (Rule 62 (a)) and the maximum tension in the conductor is only 324 pounds, the required factor of safety (2) is amply met.

9.

Crossarms.

Crossarms

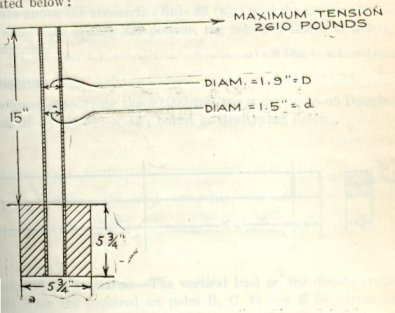

supporting the 60,000 volt wires are to be of Douglas fir, dimensions 5Ύ X 5

Ύ X 12, bored as illustrated below:

Dead load on crossarms - The vertical load on the double crossarms (double arms are required on poles B, C, D and E by virtue of the double pin requirement) under maximum conditions of loading will be for each conductor equal to the weight per foot of wire (since no ice loading is considered) times one-half the sum of the length of the crossing and adjacent spans or

![]()

The weight per arm for conductors is 36 pounds.

Bending moment per arm

![]()

The point of maximum bending moment will be at the trough bolt attaching the arm to the pole, at which point the cross-section of the arm is reduced by the amount of the bolt hole.

The following shows the method of figuring the fiber stress at this point for one crossarm:

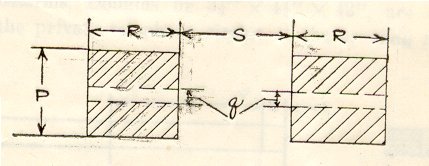

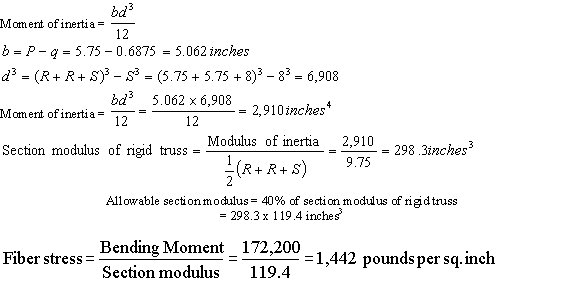

![]()

![]()

As the

ultimate fiber stress is 5,400 pounds per square inch, the stress due to the

dead load with safety factor 4 is unimportant.

The dead

load on the telephone crossarm computed in a similar manner is found to be 16.2

pounds per square inch.

In the

above calculations no account has been taken of weight of pins and insulators

and no allowance made for additional strength afforded by crossarm braces.

10. Unbalanced Wire Load on Crossarms.

It is

assumed that double crossarms (5Ύ X 5Ύ X 12) will be employed space 8

inches apart, the separation being maintained by spreader blocks and

bolts. Crossarm construction of this

type is assumed to have 40 percent* of the

strength of two crossarms of the same dimensions connected as a rigid truss.

*When double crossarms are connected together

at the ends with spacing blocks, bolts or plates, their combined strength in

the direction of the pull of the conductors is in excess of double the strength

of a single crossarm and is less than the strength of two crossarms of similar

strength dimensions and spacing, connected as a rigid truss.

Allowance is made for this in the following manner:

(a) Double wood or steel crossarms, attached to poles, connected together at the ends by bolts with spacing nuts and washers or by bolts with pipe spacers of thirty (30) percent of the strength of two crossarms, of similar dimensions and spacing, connected as a rigid truss.

(b) Double wood or steel crossarms, , attached to poles, connected together at the ends by spacing blocks or plates, bolted or riveted to the crossarms will be considered as having a strength not in excess of forty (40) percent of the strength of the strength of two crossarms, of similar dimensions and spacing, connected as a rigid truss.

(c) Steel crossarms designed to take shear between the main members will be allowed a factor of strength in accordance with their construction.

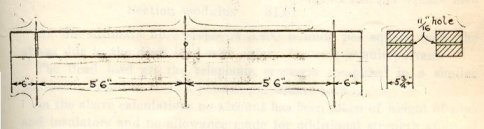

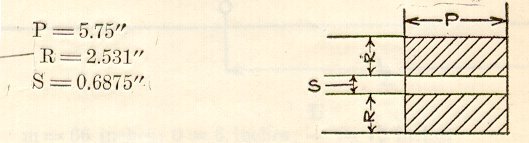

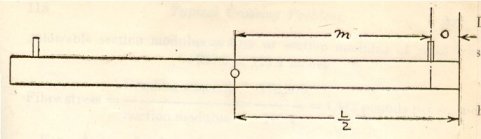

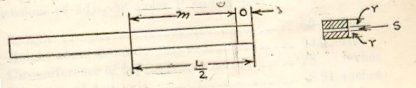

m = 66 inches; o = 6 inches; ![]()

Pull = 2,610 pounds on each pin

As it is necessary to consider the total load applied to one side only, the total bending moment is

2,610 X 66 =172,200 inch-pounds

Section of Double Crossarms.

P=5.75 q (diameter of bolt hole) = ![]() R=5.75 S = 8

R=5.75 S = 8

For a factor of safety of 4 required by the rules the allowable fiber stress is 1,350 pounds.

Thus double crossarms of this type upon the crossing poles C and D only would not be sufficient to meet the strength requirements. However, since, as previously discussed, double pins of the type employed herein are required at poles B, C, D and E, double crossarms are also required at the same poles and the strength requirements are therefore amply met.

Single crossarms, Douglas fir 3 Ό X 4 Ό X 42, are assumed for supporting the private telephone circuit at the crossing and the adjacent spans.

Since the allowable fiber stress for factor of safety 4 is 1,350 pounds the stress sue to the unbalanced load is well within the limit.

11. Poles

The crossing poles are Western red cedar and their dimensions, considering the clearances required, are as follows:

Length 55 feet

Height above ground 48 feet

Circumference at top 28 inches

Diameter at top 8.91 inches

Circumference 6 feet from butt 49 inches

Distance from ground line to conductors supported is given as follows:

Top supply conductors 487

Middle supply conductors 431

Lower supply conductors 377

Private telephone conductors 286

Ground level at base of pole is considered to be at the same elevation as top rail.

Dimensions of adjacent poles B and E are

Length 50 feet

Height above ground 43.5 feet

Circumference at top 28 inches

Diameter at top 8.91 inches

Circumference 6 feet from butt 47 inches

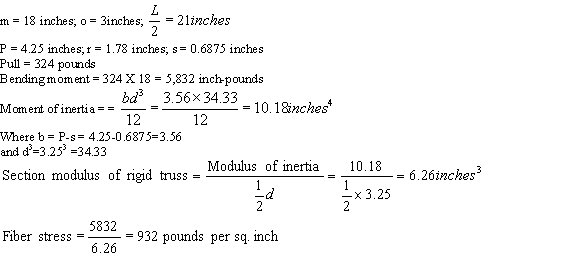

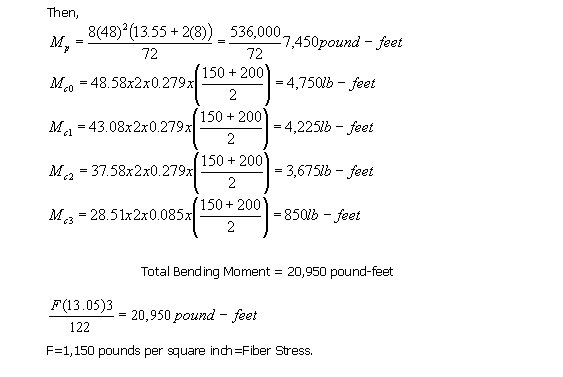

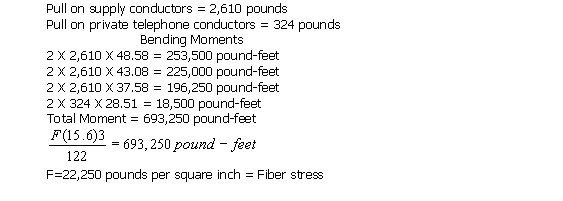

12. Transverse Load on Poles C and D

Due to 8-pound wind on projected areas of pole and conductors, maximum stress assumed at ground line.

The approximate moment at the ground, due to wind pressure on pole, is

![]()

where

P=Pressure

in pounds per square foot on projected area of pole

H=Height of

Pole above ground

D1=Diameter

of pole at ground in inches.

D2=Diameter

of pole at top in inches.

The moment

![]()

Where:

Ph = Horizontal load per lineal foot due to an 8 pound wind pressure on projected area of wire

L = Height of conductors above ground in feet

n = Number of wires

S1 and S2 = Length of crossing and adjacent spans, respectively

Mp = Moment due to wind pressure on pole

Mc0 = Moment due to pressure on top supply conductors

Mc1 = Moment due to pressure on middle supply conductors

Mc2 = Moment due to pressure on lower supply conductors

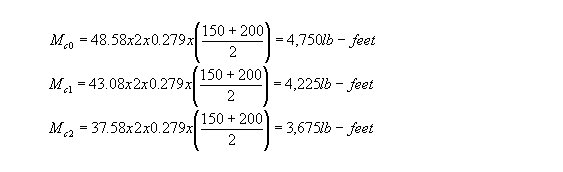

Mc3 = Moment due to pressure on telephone conductors

Total Moment =Mp + Mc0 + Mc1 + Mc2+ Mc3

![]()

Moment due to supply wires:

Ph = 0.279 pounds per linear foot for No. 00

A.W.G. copper, stranded, bare

Moment due to telephone conductors:

Ph = 0.085 pounds per linear foot for No. 8

A.W.G. copper, solid, bare

The allowable fiber stress for Western red cedar poles to provide a factor of safety of 4 is 1,275 pounds, hence the crossing poles do not require to be side guyed.

If poles of the minimum dimensions given in Rule 126(b) 3 were employed as is permissible, then

Length 55 feet

Height above ground 48 feet

Circumference at top 25.1 inches

Diameter at top 8 inches

Circumference 6 feet from butt 41 inches

Diameter 6 feet from butt 13.05 inches

The minimum sized poles thus permitted will also meet the requirements for transverse load without the use of side guys.

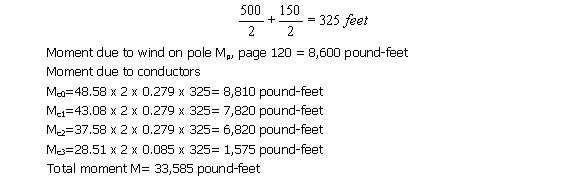

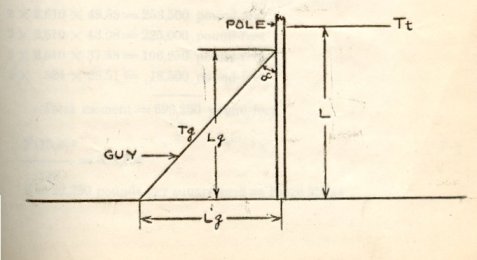

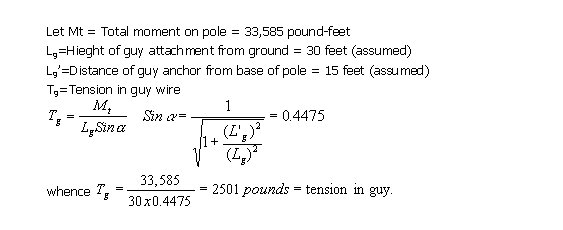

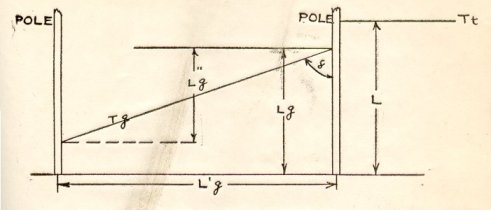

13. Side Guying

If side guying were required for poles C and D, and it was assumed physically impossible to side guy these poles, then poles B and E should be side guyed and the entire line between them must be Grade A, except as to transverse strength of poles, which shall not be dimensions smaller than set forth in Rule 126 (b) 3. The method of figuring side guys for poles B and E is as follows:

Side guys are figured to take the entire transverse load (between the guyed poles B and E), the pole acting simply as a strut.

The transverse force acting on the poles will be due to wind pressure on the pole and the transverse wind pressure on the conductors supported. The length of conductor used in figuring this transverse force will be equal to one-half the distance between the guyed poles B and E, plus one-half the length of the span adjacent to these poles, or to

The specified factor of safety for guys is 3, hence a guy having an ultimate strength of not less than 7,503 pounds should be employed which can be obtained by using one Siemens-Martin 7/16- inch guy its equivalent having an ultimate strength of 9,000 pounds.

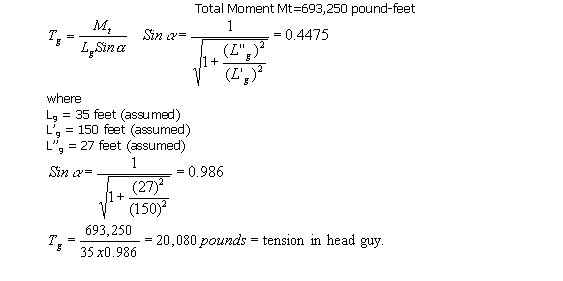

14. Unbalanced Load on Crossing Poles C and D.

(Rule 126 (b) 2) To withstand at all times without failure, the unbalanced stress due to the combined pull toward the crossing of all the conductors supported, the pull in each conductor being taken as the tension due to the specified loading

The allowable fiber stress under this unbalanced load is 5,100 pounds per square inch, hence poles C and D must be head guyed.

Under an unbalanced longitudinal stress as above considered, the pole, or, in this case the guy can be figured to withstand this unbalanced stress without failure; that is the guys can be figured, therefore, guys with ultimate strength of 20,080 pounds. There can be used, therefore, three 3/8 inch Siemens-Martin steel strands or equivalent having an ultimate strength of 11,000 pounds each. The unbalanced stress may be assumed to be distributed over one or more poles adjacent to the crossing poles. If so assumed one head guy may be installed on each of the crossing poles C and D and also on each of the adjoining poles B and E, each of these guys to be ½-inch Siemens-Martin galvanized steel strand or equivalent having an ultimate strength of 11,000 pounds.